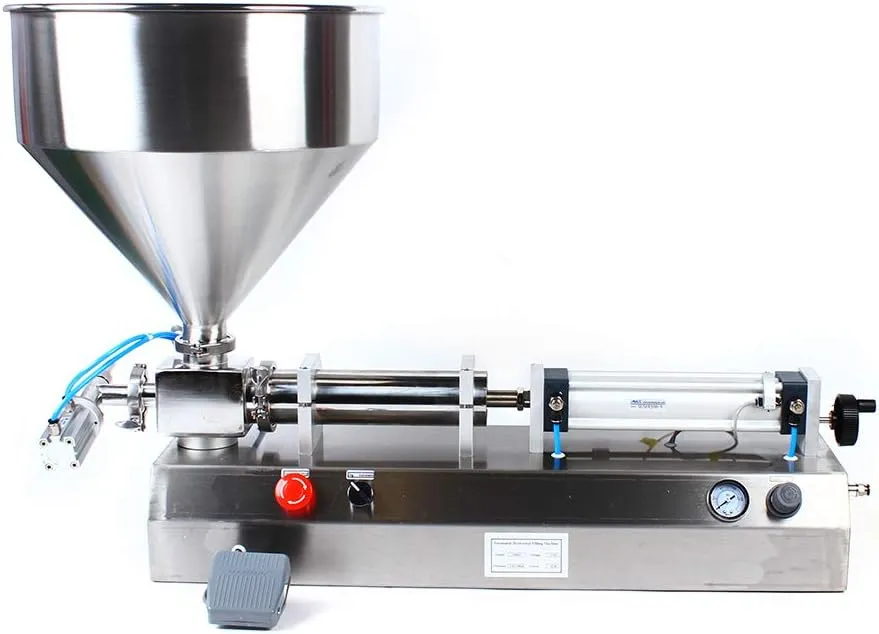

- ★【Pneumatic Liquid Filling Machine】This Pneumatic Liquid Filling Machine has an efficient filling performance. Equipped with a hopper with a large inlet volume at once.

- ★【High Accuracy】Filling scalar scale, quantitative filling, accurate and efficient; independent rotary valve cylinder, fully guarantee the closure of rotary valve, not easy to drip

- ★【Excellent Performance】Pneumatic Liquid Filling Machine adoping foot pedal and automatic filling methods can be switched at will.

- ★【Convenient operation】Cylinder homing knob, convenient operation, stable and durable; with filling speed adjustment knob, combined with the principle of mechanics, durable and stable.

- ★【Various Application】Pneumatic Liquid Filling Machine is suitable for all liquid and paste without particles, like cream, shampoo, oil, toothpaste. Perfect for usage in any fields.

Product Description

This equipment is a filling machine for filling high-viscosity flow. It uses the three-way principle of a cylinder to drive a piston and a rotary valve to extract and eject high-viscosity materials, and use a magnetic ring switch to control the stroke adjustment of the cylinder Filling volume.

Product Parameters

Voltage: 110v 60HZ

Size: Machine 110*45*30cm

Hopper: 50*50*50cm

Weight: 55kg

Working method: pneumatic

Filling speed: about 1-30 bottles/min

Single filling range: 50-500ml

Air pump power: 800w

Working pressure: 0.6MPA

Filling accuracy: ≦±1%

Packing List

Machine hopper sealing ring wrench manual

Key Words

1. High accuracy

Filling scalar scale, quantitative filling, accurate and efficient; independent rotary valve cylinder, fully guarantee the closure of rotary valve, not easy to drip

2. Convenient operation

Cylinder homing knob, convenient operation, stable and durable; with filling speed adjustment knob, combined with the principle of mechanics, durable and stable,

Excellent performance; foot pedal and automatic filling methods can be switched at will

3. Lasting work

Large-capacity stainless steel hopper, can work continuously, not easy to rust

4. Wide application range

Food, cosmetics, and industrial products can be filled

Customer Notice

1. Regarding cleaning: The rotary valve is made of wear-resistant, acid-resistant, and high-temperature resistant tetrafluoroethylene material, so you can't knock and collide at will

2. The main power of the machine is air source, customers need to prepare their own air pressure equipment

3. Influencing factors of filling speed: the viscosity of the material, the stroke of the cylinder, the size of the filling, the proficiency of the operator

4. Description of the viscosity of the filling material: the thickest can only be filled with the viscosity of toothpaste, and the viscosity is smaller than it.